M3051-000005-100PG: Description, Features, and Applications

Global electronic component supplier ERSAELECTRONICS: Rich inventory for one-stop shopping. Inquire easily, and receive fast, customized solutions and quotes.

What is a M3051-000005-100PG?

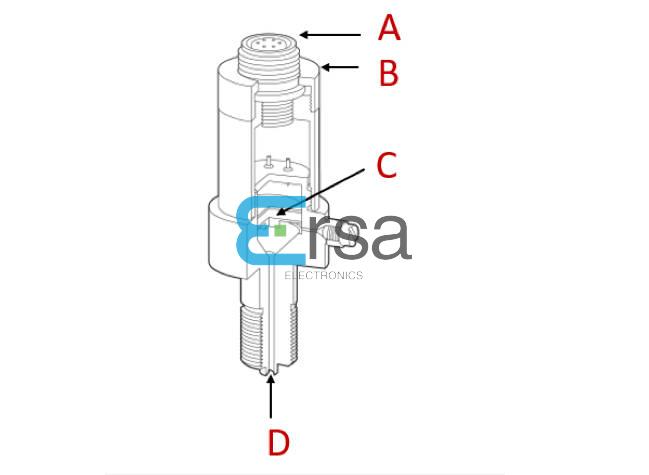

The M3051-000005-100PG is a pressure transducer produced by TE Connectivity as part of their Microfused™ line. Designed for measuring both liquid and gas pressure, it is ideal for applications across various sectors, including industrial, automotive, and agricultural environments. Constructed from durable 17-4 PH stainless steel, the transducer features a one-piece machined design that eliminates the need for O-rings or welds, ensuring a leak-proof and highly compatible system.

.jpg)

It can measure pressures up to 100 psi (approximately 689.5 kPa) in a gauge configuration and provides analog output in either mV or amplified signals. With an accuracy of ±1% and long-term stability of 0.25% over one year, the M3051-000005-100PG offers reliable performance. Key specifications include a 5V supply voltage, 1 MΩ output load, a 1 kHz bandwidth, and a low noise level of 2 mVRMS. This transducer is well-suited for a variety of applications, such as sensing and instrumentation, automotive systems, industrial processes, test and measurement setups, and agricultural monitoring. Overall, it is a robust and precise solution for high-volume use in demanding conditions.

Key Features of M3051-000005-100PG

The M3051-000005-100PG is a pressure transducer from TE Connectivity's Micro fused™ line, designed for high-performance applications in measuring liquid or gas pressure. Here are the key features:

Construction:

- One-piece machined from 17-4 PH stainless steel, ensuring durability and compatibility with various media.

- No O-rings, welds, or organics are exposed to the pressure media, allowing for a leak-proof and robust design.

Pressure Range:

- Capable of measuring up to 100 psi (approximately 689.5 kPa) with a gauge-type configuration.

Output Type:

- Provides analog output options, either as mV or amplified signals.

Accuracy and Stability:

- Accuracy of ±1%.

- Long-term stability of 0.25% spans over one year.

- Electrical Specifications:

- Supply Voltage: 5V DC.

- Output Load: 1 MΩ.

- Bandwidth: 1 kHz (-3dB).

- Noise Level: 2 mVRMS output noise.

Applications:

- Suitable for use in sensing and instrumentation, automotive, industrial processes, test and measurement setups, and agricultural monitoring systems.

M3051-000005-100PG Specifications

| Specification | Details |

| Manufacturer | TE Connectivity |

| Series | Micro fused™ |

| Pressure Range | Up to 100 psi (689.5 kPa) |

| Construction | 17-4 PH stainless steel, one-piece, no O-rings |

| Output Type | Analog (mV or amplified signals) |

| Accuracy | ±1% |

| Stability | 0.25% span per year |

| Supply Voltage | 5V |

| Output Load | 1 MΩ |

| Bandwidth | 1 kHz (-3 dB) |

| Noise Level | 2 mVRMS output noise |

| Applications | Industrial, automotive, agricultural, instrumentation, sensing |

The M3051-000005-100PG is a pressure transducer from TE Connectivity’s Micro fused™ line, designed to measure liquid and gas pressures up to 100 psi with high accuracy and stability. Its durable stainless steel construction makes it suitable for challenging environments. Offering analog outputs, the transducer ensures precision in applications like industrial automation, automotive systems, and agricultural monitoring. Its long-term stability and robust design make it ideal for high-volume applications requiring reliable pressure measurement.

Advantages of Using M3051-000005-100PG

The M3051-000005-100PG pressure transducer offers several advantages that make it suitable for a wide range of applications. Here are the key benefits:

Durable Construction: The transducer features a one-piece machined design made from 17-4 PH stainless steel, ensuring high durability and resistance to harsh environments. This eliminates the risk of leaks as there are no O-rings, welds, or organics exposed to the pressure media.

High Accuracy: With an accuracy of ±0.25% FS, the M3051-000005-100PG provides precise pressure measurements, making it ideal for applications that require reliable data.

Wide Operating Temperature Range: The device operates effectively in extreme temperatures ranging from -40°C to +125°C, allowing it to be used in diverse industrial settings without performance degradation.

Compatibility with Various Media: Its design allows for the measurement of liquid and gas pressures, including challenging media like contaminated water and mildly corrosive fluids, broadening its application scope.

Analog Output Options: The transducer provides analog output signals, which are compatible with various data acquisition systems and control devices, facilitating easy integration into existing systems.

Long-Term Stability: The sensor is designed for long-term stability with a long-term drift of only 0.25% span over one year, ensuring consistent performance over time.

Compact Size and Standard Connections: It includes a standard 1/4 NPT pipe thread, making installation straightforward and compatible with many existing systems.

These advantages make the M3051-000005-100PG an excellent choice for applications in industrial automation, automotive systems, HVAC, medical equipment, and more.

M3051-000005-100PG Applications

The M3051-000005-100PG pressure transducer is versatile and suitable for a wide range of applications across various industries. Here are the primary applications for this device:

Industrial Automation Control:

- They are used to monitor and regulate pressure in systems such as pumps, compressors, and hydraulic systems, ensuring efficient operation and safety in industrial settings.

Liquid and Gas Pressure Monitoring:

- Ideal for monitoring pressures in liquid and gas systems, including water treatment facilities, gas transmission systems, and boiler control systems.

Process Control:

- Employed in industries like petrochemicals, chemical processing, and food production to ensure safe and efficient operations by providing accurate pressure sensing and control.

HVAC Systems:

- Utilized for pressure monitoring in heating, ventilation, and air conditioning systems to maintain optimal performance and prevent failures due to excessive pressure variations.

Medical Equipment:

- Used in medical devices such as ventilators and oxygen supply systems to monitor gas pressures, contributing to patient safety and equipment reliability.

Liquid Level Monitoring:

- Can be applied in applications where liquid levels need to be monitored through pressure measurements, enhancing process control in various environments.

M3051-000005-100PG Equivalents

| Model | Manufacturer | Pressure Range | Output Type | Accuracy | Construction | Applications |

| Honeywell 19C100PG3K | Honeywell | 100 psi | Analog (mV output) | ±0.25% | Stainless steel | Industrial, automotive, medical |

| Amphenol LM-100G-P | Amphenol Advanced Sensors | 100 psi | Analog (amplified) | ±1% | Stainless steel, oil-filled | Industrial, instrumentation, HVAC |

| TE Connectivity MS5803-01BA | TE Connectivity | 100 psi | Digital (I2C, SPI) | ±0.2% | Stainless steel | Industrial, automotive, portable devices |

| WIKA S-11 | WIKA | 100 psi | Analog (amplified) | ±0.5% | Stainless steel, hermetically sealed | Industrial, automation, process control |

The M3051-000005-100PG pressure transducer has several equivalents, such as the Honeywell 19C100PG3K and Amphenol LM-100G-P. These alternatives share similar pressure ranges of 100 psi and are designed for industrial and automotive applications. They feature durable stainless steel construction and offer analog or digital outputs. The main differences are in accuracy, with options like the MS5803-01BA providing digital output and higher precision for applications requiring advanced sensing capabilities. These equivalents are reliable choices for environments requiring high precision and stability in pressure measurements.

Working Principle of M3051-000005-100PG

The M3051-000005-100PG pressure transducer operates based on a sophisticated working principle that combines advanced materials and technology for accurate pressure measurement. Here’s an overview of its working principle:

Microfused™ Technology: The M3051 employs TE Connectivity’s proprietary Microfused™ technology, which integrates micro-machined silicon piezoresistive strain gauges with high-temperature glass fused to a stainless steel diaphragm. This design allows for high accuracy and stability in pressure sensing.

Pressure Measurement: The device measures gauge pressure, which is the pressure relative to atmospheric pressure. When the pressure from the medium (liquid or gas) acts on the diaphragm, it causes a deformation proportional to the applied pressure.

Strain Gauge Response: As the diaphragm deforms, it alters the resistance of the piezoresistive strain gauges. This change in resistance generates an electrical signal that corresponds to the applied pressure.

Analog Output: The transducer provides an analog output, which can be either in millivolts or as an amplified signal. This output is compatible with various data acquisition systems and control devices, facilitating integration into different applications.

Durable Design: The one-piece construction from 17-4 PH stainless steel ensures that there are no O-rings or welds exposed to the medium, enhancing durability and preventing leaks. This robust design allows it to function effectively in harsh environments, including those involving contaminated or mildly corrosive fluids.

Temperature and Stability: The sensor operates effectively across a wide temperature range of -40°C to +125°C, maintaining accuracy and stability with a long-term drift of only 0.25% span over one year.

This combination of advanced materials, precise engineering, and innovative technology makes the M3051-000005-100PG a reliable choice for various industrial applications requiring accurate pressure measurement.

M3051-000005-100PG Compared to other pressure transducers

When comparing the M3051-000005-100PG pressure transducer to other pressure transducers, several key factors come into play, including construction, accuracy, operating range, and application suitability. Below is a comparison of the M3051 with similar models, highlighting its advantages and unique features.

| Feature/Model | M3051-000005-100PG | Honeywell ASDX Series (ASDXACX100PGAA5) | Other TE Connectivity Models (e.g., MSP300) |

| Pressure Range | 0 to 100 PSI (0 to 689.5 kPa) | 0 to 100 PSI (0 to 689.5 kPa) | Varies; e.g., up to 10,000 PSI available |

| Accuracy | ±0.25% FS | ±0.25% FS | Typically ±1% FS |

| Operating Temperature Range | -40°C to +125°C | -40°C to +125°C | -20°C to +85°C for some models |

| Construction Material | 17-4 PH stainless steel | Stainless steel | Stainless steel for durability |

| Output Type | Analog (mV or amplified) | Analog voltage output (0-5V) | Analog output (4-20 mA or mV options) |

| Long-term Stability | 0.25% span over one year | Not specified | Varies; typically less stable than M3051 |

| Design Features | No O-rings, welds, or organics exposed | Standard design with O-rings | Similar robust designs without O-rings |

| Applications | Industrial automation, HVAC, medical | General industrial applications | Broad applications including automotive |

Key Advantages of M3051-000005-100PG

Durability and Reliability: The one-piece construction from 17-4 PH stainless steel enhances durability and ensures a leak-proof system without the use of O-rings or welds, making it suitable for harsh environments and contaminated media.

High Accuracy and Stability: With an accuracy of ±0.25% FS and excellent long-term stability, the M3051 is particularly advantageous for applications requiring precise measurements over extended periods.

Wide Operating Temperature Range: The ability to operate effectively from -40°C to +125°C allows for versatility in various industrial applications.

Flexible Output Options: The M3051 offers both millivolt and amplified output options, providing compatibility with a wide range of data acquisition systems and control devices.

The M3051-000005-100PG stands out among pressure transducers due to its robust design, high accuracy, and versatility across various applications. While other models may offer similar pressure ranges or accuracy levels, the unique construction and stability of the M3051 make it a preferred choice in demanding environments where reliability is critical.